Fokus auf breitbandige SATCOM-Datenanbindung während der Fahrt. Erste Anwendungen umfassen kommerzielle Fahrzeuge und solche der Sicherheitsbehörden

EnSilica (AIM: ENSI), ein führender Anbieter von Mixed-Signal-ASICs und SoCs, gibt bekannt, die VITES GmbH mit einem neuen Beamforming-Chipsatz (elektronische Funkstrahl-Formung) für Satelliten-User-Terminals zu beliefern. VITES wird die ASIC-Entwicklung maßgeblich begleiten und den Chipsatz in seinen neuen ViSAT-Ka-Band-Terminals einsetzen.

Der Beamforming-Chipsatz von EnSilica ist daraufhin optimiert, energie- und kosteneffiziente, bodengestützte Flat-Panel-User-Terminals für Satellitenkommunikationssysteme realisieren zu können, die sich für ortsfeste SATCOM- und mobile SATCOM-on-the-Move-/Communications-on-the-Move Anwendungen eignen.

VITES ist auf Breitband-Funksysteme für professionelle Anwendungen spezialisiert und liefert seit 2019 Flat-Panel-Terminals auf Basis einer eigenen Phased-Array-Technologie.

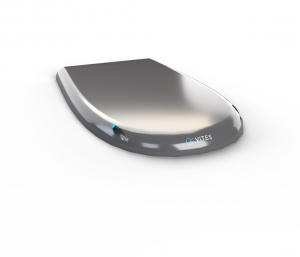

Integriert in Fahrzeuge, ermöglicht das neue ViSAT-Ka-Band-Terminal der VITES die Konnektivität mit Satelliten während der Fahrt (Communications-on-the-Move, COTM). Das Terminal ist in der Lage, den Funkstrahl vollelektronisch auf die Bewegung von erdnahen Satelliten (LEO, Low Earth Orbit) und anderen nicht geosynchronen Satelliten (NGSO) nachzuführen. Nutzer erhalten damit einen schnellen Netzwerkzugang überall auf der Welt, auch während der Fahrt.

ViSAT-Ka basiert auf einer skalierbaren Architektur, die sehr energieeffiziente TDD- und FDD-Terminals zu erschwinglichen Preisen ermöglicht. Auf dieser fortschrittlichen technischen Basis entwickelt VITES Terminals für Land- und Seefahrzeuge aller Art – auch für kostensensitive Automotive-Anwendungen, die zudem eine sehr geringe Verlustleistung erfordern.

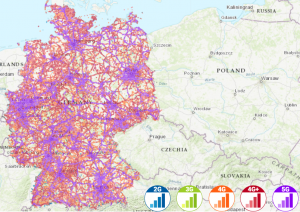

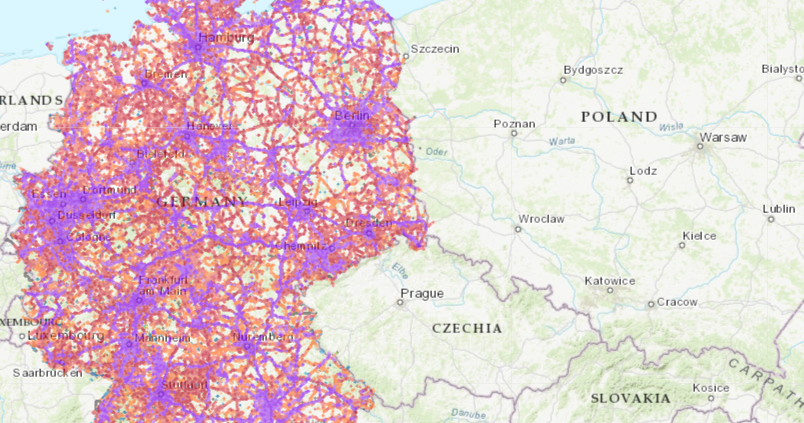

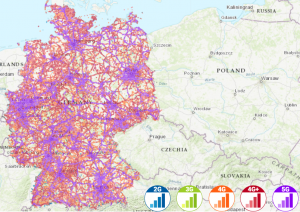

Mit dieser Technologie haben Fahrzeuge auch außerhalb der 4G-/5G-Netzabdeckung Zugang zu „Always-on“-Breitbandverbindungen mit hohem Durchsatz – und das in einer sehr flachen, kompakten Formgebung, die sich gleichermaßen für Nachrüstungen, als auch für die Fahrzeug-Erstausrüstung ab Werk eignet.

Paul Morris, VP der RF and Communications Business Unit bei EnSilica, dazu:

„EnSilica investiert seit mehreren Jahren in diesen Bereich und arbeitet eng mit der UK Space Agency, der European Space Agency und der VITES GmbH zusammen. VITES hat klare Anforderungen für die Beamforming-Chips geliefert, so dass wir unsere Lösung für den Markt optimieren konnten. Der Chipsatz lässt sich mit Ka- und Ku-Band-RFICs kombinieren, einschließlich unserem EN92030 Ka-band-Chip, so dass er die verschiedenen LEO- oder GEO-Konstellationen abdeckt.“

Martin Gassner, CEO von VITES, fügte hinzu:

„Für die kommenden NGSO-Konstellationen sind Terminals erforderlich, die in Bezug auf Performance, Energieeffizienz und Herstellungskosten einen Quantensprung darstellen. Diese Anforderungen erfüllen wir mit unseren neuen ViSAT-Ka-Band-Terminals. Wir freuen uns über die Partnerschaft mit EnSilica und die Zusammenarbeit bei der Entwicklung von COTM-Lösungen, die Breitbandverbindungen auch dort ermöglichen, wo es keinen Zugang zu terrestrischen Netzen gibt.“

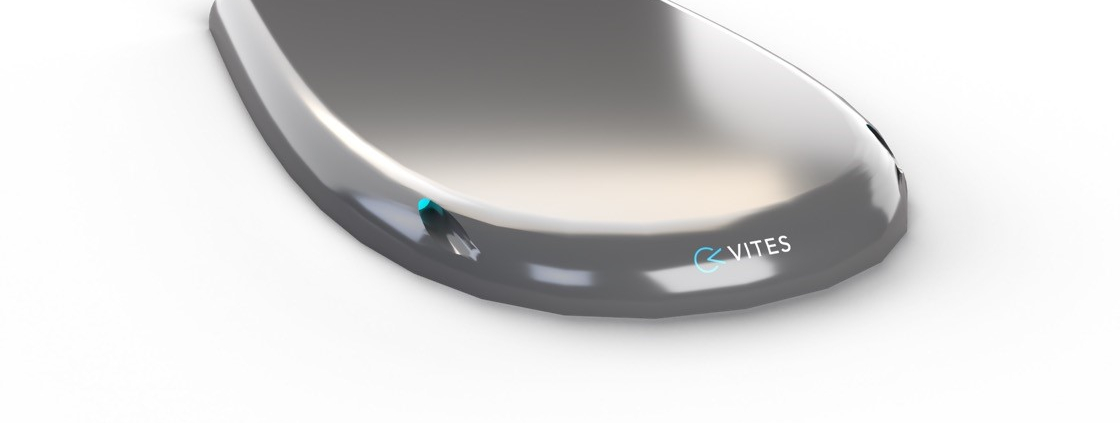

Bild 1: Das ViSAT-Ka-Band-Terminal misst je nach Version zwischen ca. 16 x 10 cm und 50 x 30 cm und ist für den Einbau in Fahrzeuge für Communications-on-the-Move vorgesehen

Bild 2: 4G- und 5G-Abdeckung in Deutschland, wobei wesentliche Gebiete von keinem Betreiber versorgt werden (Quelle: nPerf).

Kontakt für weitere Informationen:

| EnSilica plc

Ian Lankshear, Chief Executive Officer

www.ensilica.com |

Via Vigo Consulting

+44 (0)20 7390 0233 |

|

VITES GmbH

Martin Gassner, Chief Executive Officer

www.vites.de

|

+49 (0)89 6088 4600

info@VITES.DE |

| Sonus PR (Technology Public Relations)

Rob Ashwell |

+44 (0)7800 515 001 ensilica@sonuspr.com.com |

Über EnSilica

EnSilica ist ein führendes Fabless-Design-Unternehmen, das sich auf kundenspezifisches ASIC-Design für Erstausrüster (OEMs) und Systemhäuser sowie auf IC-Designdienstleistungen für Firmen mit eigener IC-Entwicklung konzentriert. Das Unternehmen besitzt erstrangige Erfahrungen in der Entwicklung kundenspezifischer HF-, mmWave-, Mixed-Signal- und Digital-ICs für internationale Kunden in den Bereichen Automotive, Industrie, Gesundheitswesen und Kommunikation. Darüber hinaus bietet das Unternehmen ein breites Spektrum an Kern-IP für Kryptographie, Radar und Kommunikationssysteme. EnSilica hat umfangreiche Erfahrung in der Lieferung qualitativ hochwertiger Dienstleistungen, die anspruchsvolle Industrienormen erfüllen. Das Unternehmen hat seinen Hauptsitz in der Nähe von Oxford, Großbritannien, und verfügt über Entwicklungszentren in ganz Großbritannien, in Bangalore, Indien, und in Port Alegre, Brasilien.

Über VITES

Die VITES GmbH („VITES“) ist ein innovativer deutscher Anbieter hochleistungsfähiger Breitband-Funksysteme und kundenspezifischer Lösungen für professionelle Anwendungen. Der Schwerpunkt liegt auf der Entwicklung von Flat-Panel-Terminals für Communications-on-the-Move-Anwendungen. Diese Terminals basieren auf einer energieeffizienten aktiven Phased-Array-Technologie, die für jede Art von Fahrzeugen geeignet ist, sowohl für den kommerziellen Einsatz als auch bei Sicherheitsbehörden.

Im Bereich öffentliche Sicherheit und Katastrophenschutz bietet VITES nomadische LTE-/5G- (ViCell) als auch breitbandige IP-Mesh-Netze (ViMesh) an. Die Marke vikomobil 2.0 steht für mobile energieautarke Mobilfunkknoten („Mobilfunkzelle auf Rädern“) die zusätzlich SATCOM integrieren.