Industrial : ASIC Design and Supply

EnSilica is your trusted partner focused on custom ASIC design for industrial and healthcare OEMs looking to deliver reliable, leading-edge solutions across a wide range of applications.

ASIC development can reduce BOM cost by as much as 80% but has historically been reserved for companies who had the high-volume production required to justify the up-front NRE costs. This has now changed. The benefits of the ASIC form factor, reliability, environmental robustness, IP protection, functional safety and security of supply now provide the compelling business case required for many applications in the industrial and healthcare markets.

Industry 4.0, Industrial IoT (IIoT) and Smart healthcare are also driving the development of new classes of devices for monitoring and control which reduce waste and increase productivity while also providing cost savings that far outweigh the investment in the underlying technology.

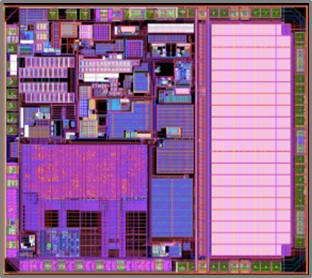

180nm BCD controller MCU for safety critical applications

EnSilica’s engineers live and breathe ASIC development every day and apply their in-depth knowledge to ensure that every project meets its requirements and is delivered on-time, on budget and right first-time. Our wealth of experience combined with our

EnSilica’s engineers live and breathe ASIC development every day and apply their in-depth knowledge to ensure that every project meets its requirements and is delivered on-time, on budget and right first-time. Our wealth of experience combined with our